BLOG

-

Pourquoi la pièce injectée en plastique se déforme-t-elle par gauchissement ?

La déformation par gauchissement fait référence à la distorsion de la forme du produit moulé par injection et au gauchissement, s'écartant des exigences de précision de forme de la pièce, c'est l'un des défauts à résoudre dans la conception et la production de moules à injection....En savoir plus -

Principaux paramètres de processus des pièces en plastique d'injection

Les principaux paramètres de processus des pièces moulées par injection peuvent être regroupés en 4 facteurs : température du cylindre, température de fusion, température du moule d'injection, pression d'injection.1. Température du cylindre : Il est bien connu que le succès des pièces moulées par injection plastique dépend de nombreux ...En savoir plus -

Surmoulage TPE

1.Qu'est-ce que le surmoulage ? Le surmoulage est un processus de moulage par injection dans lequel un matériau est moulé dans un deuxième matériau.On parle ici principalement de surmoulage de TPE.Le TPE est appelé élastomère thermoplastique, c'est un matériau fonctionnel avec à la fois une élasticité en caoutchouc et une sti...En savoir plus -

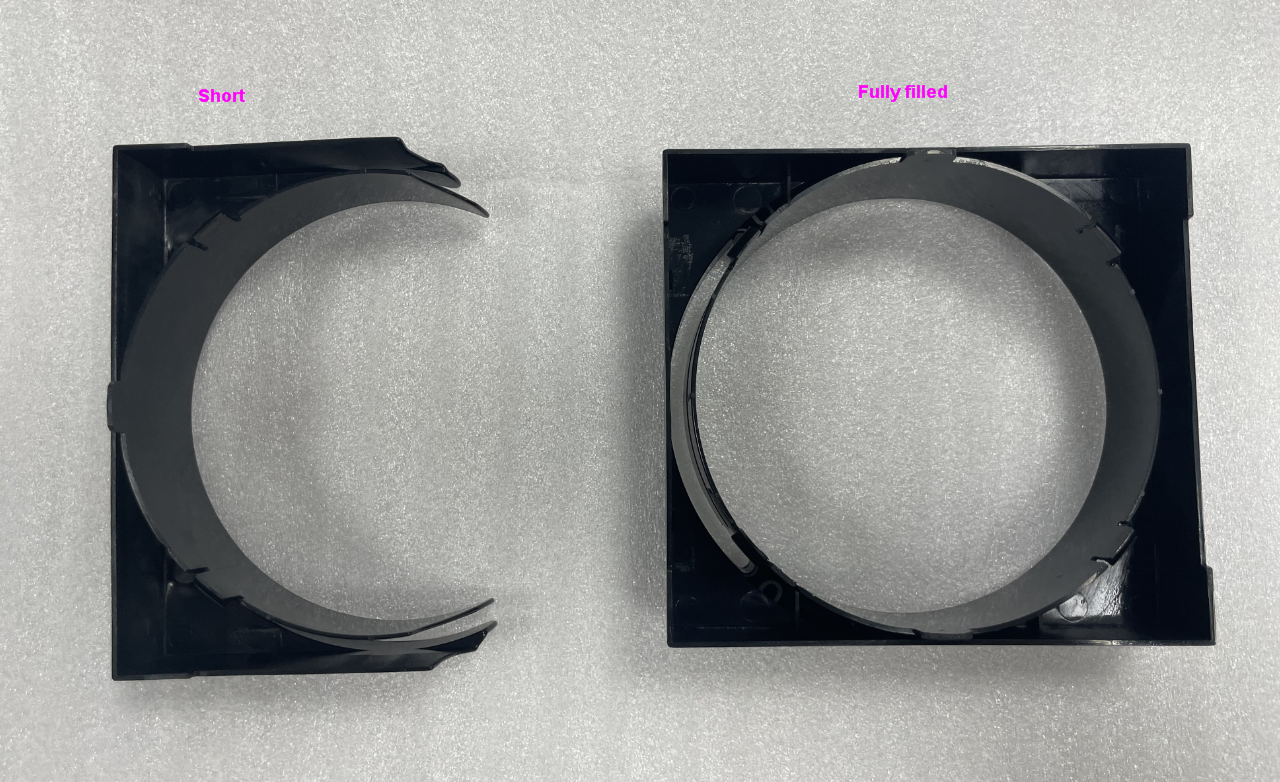

Pourquoi la pièce en plastique n'est pas entièrement injectée ?

Dans le moulage par injection, l'injection à tir court, également appelée sous-remplissage, fait référence à la fin du flux de plastique d'injection du phénomène d'incomplétude partielle ou à une partie d'une cavité de moule qui n'est pas remplie, notamment la zone à paroi mince ou la fin du flux. zone de chemin.Les performances de la fonte...En savoir plus -

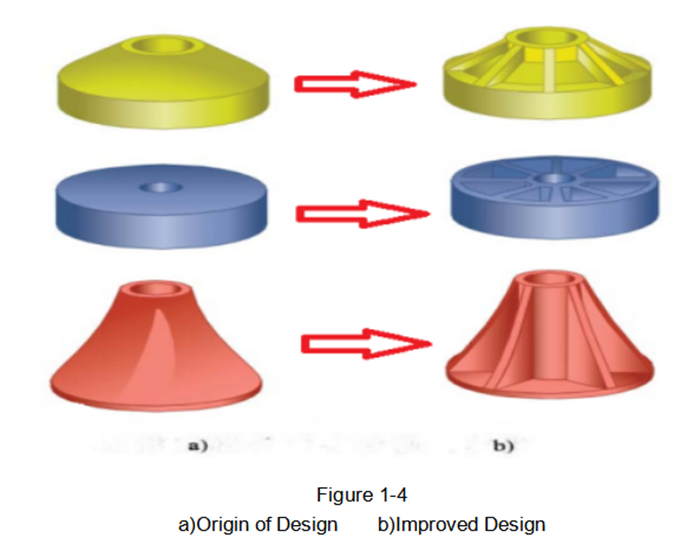

Calcul de l'épaisseur de paroi des pièces en plastique moulées par injection

Dans la conception de pièces en plastique, l'épaisseur de paroi de la pièce est le premier paramètre à considérer, l'épaisseur de paroi de la pièce détermine les propriétés mécaniques de la pièce, l'aspect de la pièce, la capacité d'injection de la pièce et le coût. de la pièce.JE...En savoir plus -

Quand utiliser le moule à injection rapide

Le moulage par injection rapide est une technologie polyvalente qui peut être utilisée pour produire une grande variété de pièces et de produits.Le processus est rapide et efficace et peut être utilisé pour produire des pièces aux géométries complexes.Le moulage par injection rapide est également une solution idéale pour le prototypage...En savoir plus -

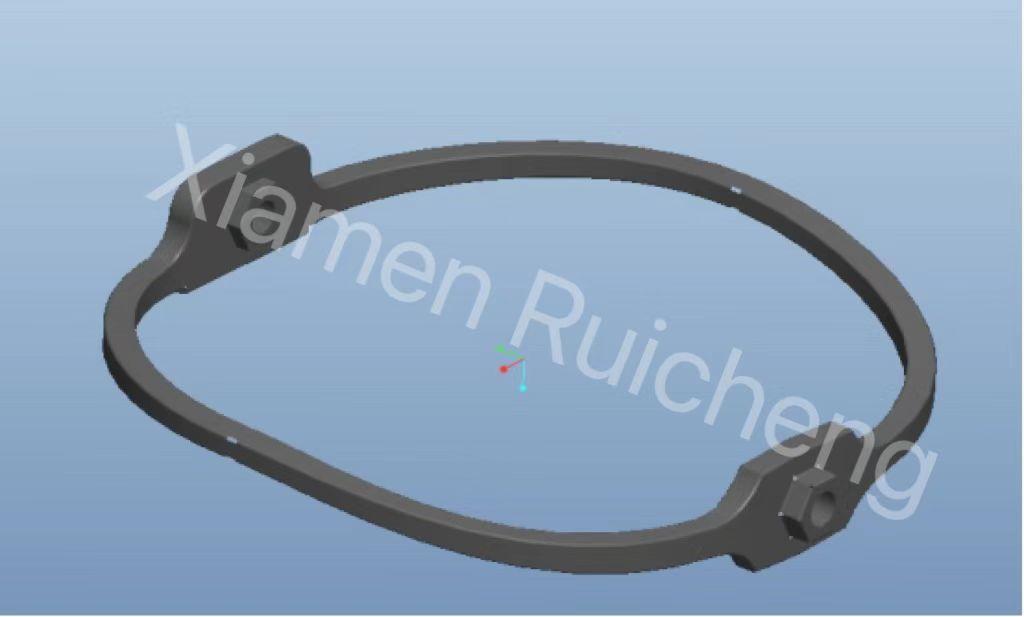

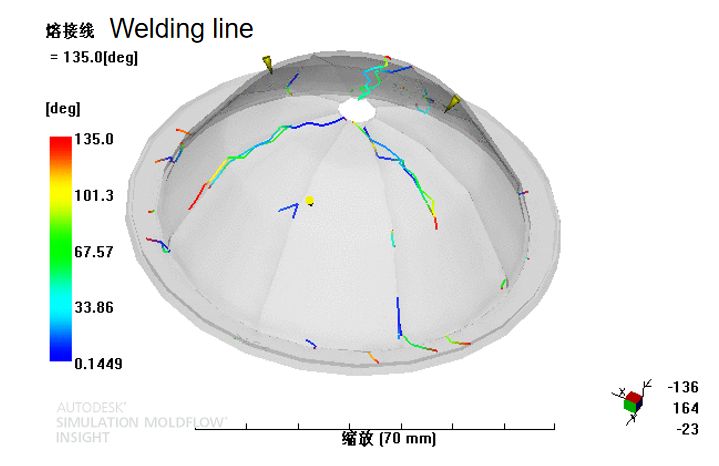

Ligne de soudage de pièces par injection plastique

Qu'est-ce qu'une ligne de soudage La ligne de soudage est également appelée marque de soudage, marque de flux.Dans le processus de moulage par injection, lorsque plusieurs portes sont utilisées ou que des trous existent dans la cavité, ou des inserts et des produits présentant de grands changements dans les dimensions d'épaisseur, l'écoulement de la matière plastique fondue se produit dans le moule en plus de 2 di...En savoir plus -

Qu'est-ce que le moulage par injection personnalisé

Le moulage par injection est un type de processus de fabrication dans lequel des pièces ou des produits sont fabriqués en injectant un matériau fondu dans un moule.Le moulage par injection peut être réalisé avec une variété de matériaux, mais utilise le plus souvent du plastique.Le moulage par injection personnalisé est un processus dans lequel du plastique est injecté dans un m...En savoir plus -

Plus que vous voulez savoir avant la production de moulage par injection plastique

Questions sur la production de moules par injection plastique Q : Pouvez-vous confirmer que nous serons propriétaires de l'outillage une fois le paiement final effectué ?Réponse de Ruicheng : La règle est toujours de savoir qui paie les moules qui les possèdent.Nous ne sommes que le fabricant...En savoir plus -

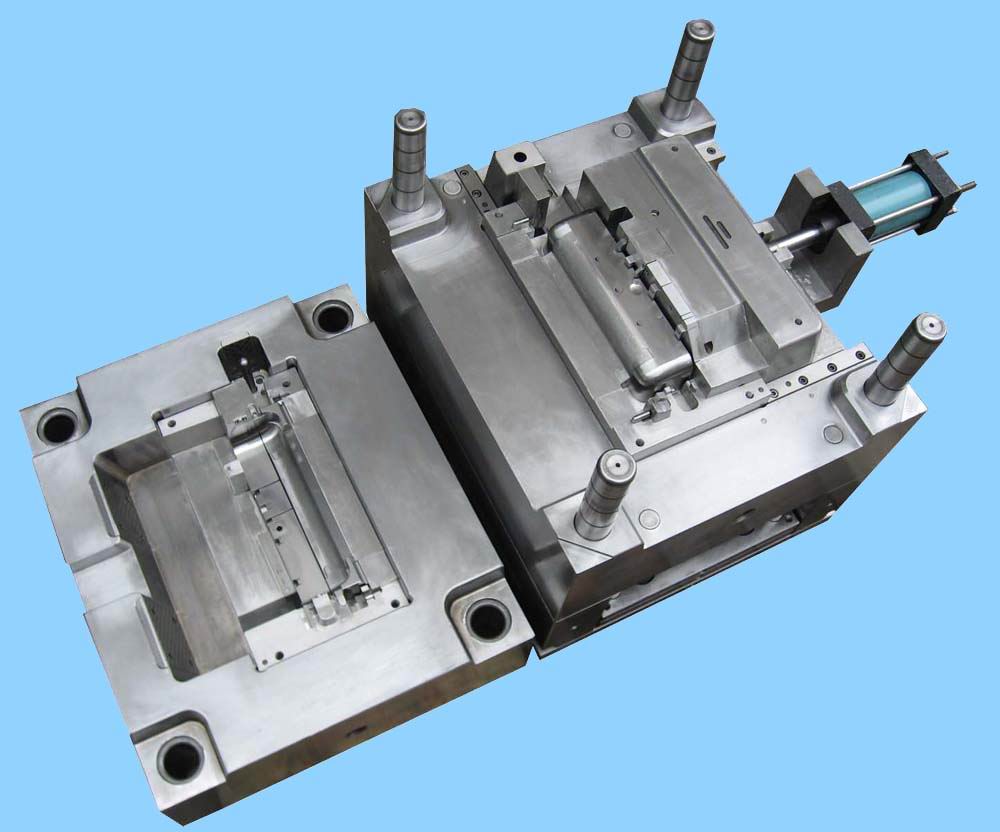

Définition de la durée de vie du moule à injection

Les moules d'injection sont le principal équipement de traitement pour la production industrielle, l'utilisation de moules pour produire des pièces en plastique, avec de nombreux avantages tels que l'efficacité de la production, la facilité de garantir la qualité, les faibles coûts de production...En savoir plus -

Quels facteurs affectent les coûts du moulage par injection plastique

Il est important de comprendre « quels facteurs affectent le prix du moulage par injection ». L'apprentissage des facteurs vous aidera à comprendre l'outillage nécessaire à votre conception et vous aidera également à choisir le fournisseur professionnel à embaucher pour vos projets. Voici quelques-uns des principaux raisons : 1. Conception Complète...En savoir plus