Chine Fabricant de coque en alliage d'aluminium de charge de voiture à nouvelle énergie de moulage sous pression

détails du produit

nous sommes en mesure de fournir des articles de qualité supérieure, des prix agressifs et une meilleure assistance aux acheteurs.Notre destination est «Vous venez ici avec difficulté et nous vous offrons un sourire à emporter» pour le fabricant chinois de coques en alliage d'aluminium de charge de voiture à énergie nouvelle moulé sous pression, tout intérêt, assurez-vous que vous n'hésitez pas à nous contacter.Nous sommes impatients de former des interactions commerciales prospères avec de nouveaux acheteurs à travers le monde dans un avenir proche.

nous sommes en mesure de fournir des articles de qualité supérieure, des prix agressifs et une meilleure assistance aux acheteurs.Notre destination est « Vous venez ici avec difficulté et nous vous offrons un sourire à emporter » pourPièces et moulage en aluminium en Chine, Avec la technologie comme noyau, développer et produire des marchandises de haute qualité en fonction des divers besoins du marché.Avec ce concept, l'entreprise continuera à développer des produits à haute valeur ajoutée et à améliorer continuellement les articles, et offrira à de nombreux clients les meilleurs produits et services !

Demande du client

1. Produisez la pièce selon le fichier 3D et contrôlez la précision à moins de 0,05 M.

2. L'inspection CMM fait référence à la tolérance du dessin 2D.

3. Assurez-vous que l'assemblage est correct.

Notre analyse

Après avoir reçu les dessins et les demandes du client, nos ingénieurs professionnels ont une analyse approfondie et la confirmation que nous pouvons produire cette pièce strictement et contrôler toutes les dimensions en tolérance.Pour nous assurer que l'assemblage est correct, nous avons demandé au client de fournir le dessin d'assemblage pour vérifier qu'il n'y a aucune interférence avec d'autres composants.

Commencer à travailler

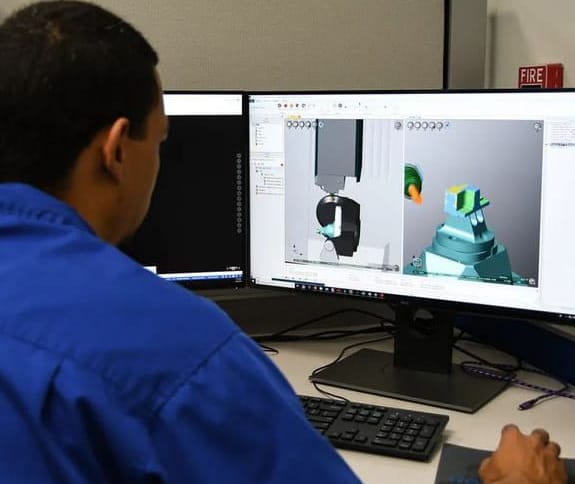

1. Programmation

Notre programmeur CNC travaille à la définition des trajectoires de travail de la machine.

2. Usinage CNC

Le produit est usiné systématiquement et en douceur selon les chemins de programme que nous avons définis.

3. Poli à la main

La surface naturelle des produits après CNC est rugueuse et comporte beaucoup de bavures et de couteaux. Notre travailleur utilise maintenant le papier de verre pour ébavurer et polir la surface afin d'avoir une pièce lisse sans arêtes vives.La pièce sera poncée du niveau de papier de verre grossier à fin (400-1500) jusqu'à ce que la surface soit lisse.

4. Inspection CMM (machine à mesurer tridimensionnelle)

Notre QC ajuste la machine CMM pour avoir une inspection précise de la précision dimensionnelle, de la précision de positionnement, de la précision géométrique et de la précision du contour.

5. Expédition

Après que notre QC ait donné son feu vert sur ce produit, nous les expédierons avec un emballage solide pour protéger le produit.Pour que chaque produit soit livré en bon état.

Cliquez ici pour en savoir plus

Nous sommes en mesure de fournir des produits de qualité supérieure, des prix compétitifs et une assistance optimale aux acheteurs.Ruicheng, fabricant de coque en alliage d'aluminium de charge de voiture à nouvelle énergie de moulage sous pression en Chine, notre destination est « Vous venez ici avec difficulté et nous vous offrons un sourire à emporter ».En cas d'intérêt, n'hésitez pas à nous contacter.Nous sommes impatients de former des interactions commerciales prospères avec de nouveaux acheteurs à travers le monde dans un avenir proche.

Après nous être engagés dans ce domaine de fabrication industrielle sur mesure, avec la technologie comme noyau, nous développons et produisons des marchandises de haute qualité en fonction des divers besoins du marché.Avec ce concept, nous continuerons à développer des produits à haute valeur ajoutée et à améliorer continuellement les articles, et présenterons à de nombreux clients les meilleurs produits et services !